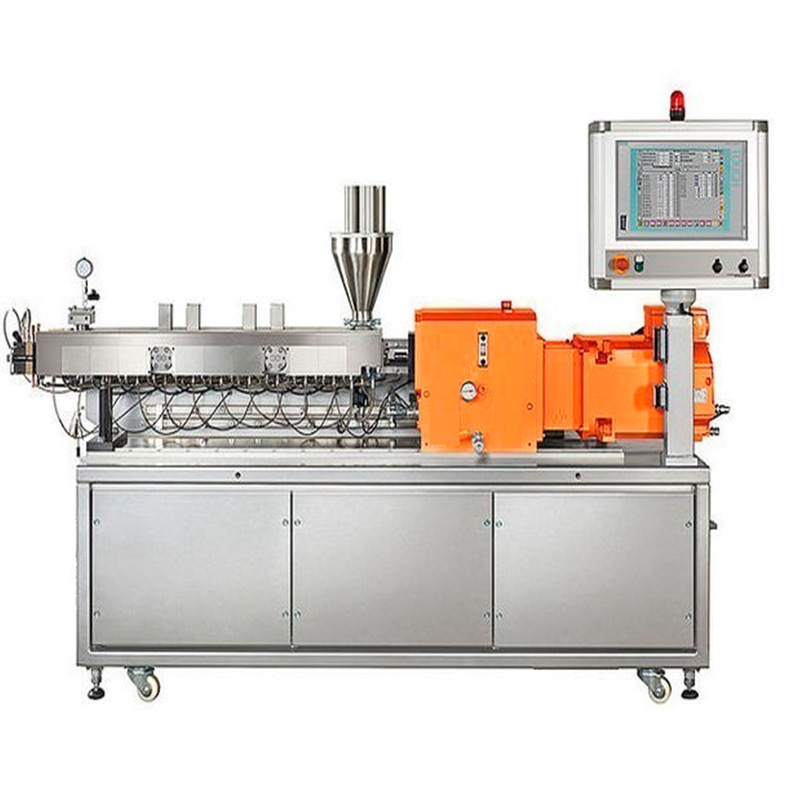

Solution Introduction

The advantages of double screw extruder for blend modification include the following: It can achieve good mixing effect; It can improve production efficiency; It can effectively improve the material properties; It has a wide range of applications.

Color masterbatch:

- High efficiency and high output.

- Good mixing effect, uniform color, and stable finished product quality.

- Wide application range, which can meet various different needs.

High filled masterbatch:

- Large output, good dispersion and mixing effect.

- Can significantly reduce the cost of the product.

- Widely applied.

Engineering plastics modification:

- An introduction to the application of the twin-screw extruder in the field of engineering plastic modification. With its unique design and excellent performance, it provides strong support for plastic modification. Through this extruder, the efficient modification of engineering plastics can be achieved, enhancing various properties of the materials and meeting the strict requirements of different fields.

- It has a variety of advantages, such as the ability to precisely control the mixing process to ensure the consistency and stability of the modification effect; high-efficiency processing capacity, which greatly increases production efficiency; and flexible application to various engineering plastics, expanding the application scope of the materials.

- The application of the twin-screw extruder in the modification of engineering plastics brings new development opportunities and potential to the related industries.